The earth’s resources are limited and must be therefore protected and used sustainably. As a manufacturing company, our Group uses a variety of raw materials, including ceramics and rare metals, and we believe it is our responsibility to actively engage in 3R (reduce, reuse and recycle) activities to protect the global environment.

In Eco Vision 2030,our Group has set out our vision for 2040 to “contribute to a global recycle-oriented society by promoting zero waste emissions” and set the targets of “achieving an over 95% effective utilization rate,” “reducing at least 1% waste intensity compared to FY2018,” and “promoting 3R activities,” as milestones to be achieved in 2030.

We will also promote sustainable and efficient use of raw materials and other resources in our supply chain.

The amount of waste generated in FY2023 was 20,906tons.

The waste intensity in FY2023 was 0.054tons/million yen for the entire Group. We achieved our target by reducing waste generation by 28.5% compared to FY2018.

We will continue to promote process improvement to reduce waste.

Trends in Volume of Waste Generated(Niterra Group)

Trends in Volume of Waste Generated(Niterra Group)We are working to go paperless to reduce waste.

In addition, we have the cooperation of our stakeholders, not only within the company, but also with other stakeholders.

As part of such efforts, we digitize contracts. We also create and distribute Integrated Reports, Sustainability Data Books, and educational booklets for employees in digital format.

We will continue our efforts to go paperless.

The effective utilization rate for the entire Group in FY2023 was 89.5%, unchanged from the previous year. We will continue to promote the effective use of waste in order to achieve our target of 95% or more by 2030.

Our company makes effective use of waste through material recycling and thermal recycling.

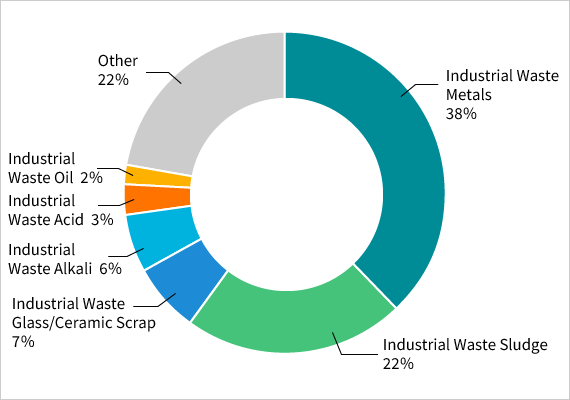

Metal waste, which accounts for the highest percentage of waste, is refined and recycled as a raw material of the same quality.

Sludge, which accounts for the next highest percentage, is mainly pre-fired ceramic material. The generated sludge is reused as a ceramic raw material or a recycled fill material.

Ceramic powder and ceramic scrap after firing are also reused.

Ceramic powder with high purity is reused as a ceramic raw material, while the rest is reused as a raw material for cement. Ceramic scrap is reused as a roadbed material.

Waste solvents are distilled and reused or reused as fuel.

Plastics are crushed and reused as raw materials for plastics or converted into RPF (solid fuel).

In addition, from the perspective of CO2 emissions, we believe that it is necessary to switch from thermal recycling to material recycling and we act accordingly.

Rate of each waste

Rate of each wasteAs part of efforts related to the Plastic Resource Circulation Act, our Group promotes reuse of packaging materials and material recycling of waste plastics.

The reuse of packaging materials is an initiative that transcends the boundaries of our Group. Packaging materials that cannot be reused within a company are provided to other companies for reuse. Companies who have received packaging materials have seen a decrease in new purchases of packaging materials.

Material recycling of waste plastics is an initiative to shift from thermal recycling to material recycling. In the manufacturing process of our Group, waste plastic containing a large amount of ceramic components is generated. We have been working to reduce the amount of waste plastic generated as much as possible, but because it is inevitable that some waste plastic is generated in the manufacturing process, we have started a new material recycling initiative.

To recycle materials, it is necessary to change the shape of the discharged material (e.g., by crushing) to suit the disposal destination, and we are working to address this issue. In addition, as part of efforts to transform waste into valuables, we compress waste styrene foam, which used to be thermally recycled, into ingots using a volume reduction machine.

Despite our active efforts (including awareness-raising) to reduce food waste in company cafeterias, there is still food waste generated. Food waste generated from the cafeteria at the Komaki Plant is transported to a biogas power plant in Komaki City, where it is converted into biogas through methane fermentation and is effectively used as fuel for power generation.

We regularly visit our waste disposers to confirm that consigned waste materials are being processed in accordance with our agreement. In FY2023, we visited 42 companies and confirmed that their waste was properly disposed of.