Chemical substances are used widely not only in the industrial field but also in various aspects of daily life because of their many excellent functions.

On the other hand, some of them are harmful to humans and the environment, and regulations regarding hazardous chemicals are becoming stricter year by year worldwide as society’s concerns about hazardous chemicals grow.

As a manufacturing company that uses chemical substances as raw materials, we believe that appropriate management of chemical substances is one of our social responsibilities.

Our Group has set the vision for 2040 of “contributing to the conservation of biodiversity through continuous implementation of appropriate chemical substance management” and set the target of “reducing environmental impact through appropriate chemical substance management,” as the milestone to be achieved in 2030.

We will also promote appropriate management of chemical substances in our supply chain.

We have a three-step management system for handling substances of environmental concern:

1. Answering requests from customers, 2. Handling within the Group, and 3. Procurement from suppliers.

Naturally we ensure compliance with laws and fulfill customer requests. More than that, we aim to reduce the use and emission of substances of environmental concern so as to minimize the impact of chemical substances on the environment and human health.

With the reinforcement of regulations on chemical substances contained in products, requests from customers in the automobile, electrical and electronics industry regarding improved compliance are increasing.

We are aware of the product content of subject chemicals such as the REACH regulation in Europe, the POPs Convention, and the TSCA regulation in the United States. When there is a request from a customer, we are taking all the appropriate measures including submission of Non-Containing Declarations, submission of various data with IMDS, JAPIA sheet, chemSHERPA, etc., and handling investigations and audits regarding our management systems.

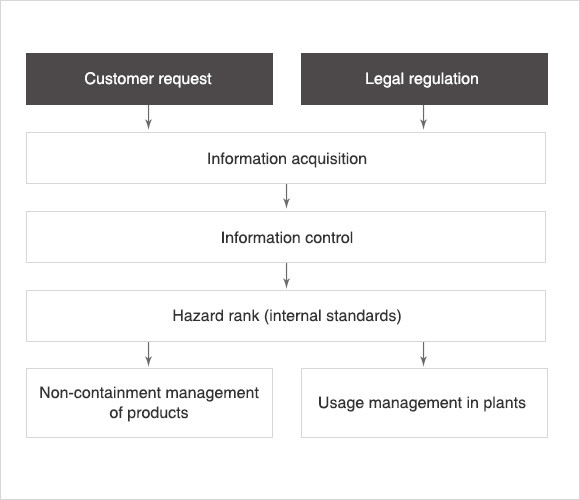

To respond appropriately to increasingly strict chemical substance regulations worldwide, we perform non-containment management for products and usage management within plants.

For hazardous chemical substances, we set hazard rankings according to toxicity and the strictness of regulations and establish handling standards for each rank.

From here on out, we will work toward substitution of hazardous chemical substances and the strengthening of management, to assure compliance with laws and with the demands of customer.

Management System

Management System| Rank | Handling standard | Substances covered |

|---|---|---|

| Prohibited substances | Use is prohibited. | Substances prohibited from use or strongly restricted by regulations. |

| Restricted substances | Safer substitutes will be sought, while making efforts to reduce the use of current substances. | Hazard level and toxicity are equivalent to prohibited substances, but an immediate changeover is impossible due to its special characteristics. |

| Monitored substances | Supplies need to be examined to find existence / non-existence of applicable substances. | Those not prohibited or restricted but that require monitoring. |

Aiming at optimized management, the respective divisions have ensured to identify and totalize PRTR substances for clarifying handling volume, release volume, and transfer volume.

Going forward, we plan to systematically introduce treatment system and reduce atmospheric emissions of VOCs (volatile organic compounds), including toluene, by half by the end of FY 2030.

To manage chemical substances contained in products appropriately, it is imperative that we gain the cooperation of our suppliers. For this reason, we request in our Green Procurement Guidelines that our suppliers not use hazardous chemical substances banned by Niterra. We designate suppliers that meet our system and material standards as Green Suppliers. In collaboration with our Green Suppliers, we promote appropriate management of hazardous chemical substances.

Our Eco Vision 2030 sets the goal of achieving 100% adoption of a green procurement system, and we will work to establish a green procurement system for the entire Niterra Group. We have begun preparations to expand this initiative to overseas factories.