Our Group is working to share and practice the concepts of TQM (Total Quality Management) in order to become a group company that creates value for all stakeholders and has a system that can respond flexibly and swiftly to change.

Based on our CSR Policy, we have updated our Corporate Quality Rules and identified the following five areas as the mainstays of total quality management (TQM).

In order to provide products and services that meet the needs of our customers and society, Our Group will establish all operations and guarantee their safety and reliability and promote development activities aimed at creating new value.

Our Group will consider methods and indicators to measure the quality of all our operations and promptly investigate the causes when results that differ from normal are obtained as well as taking countermeasures to maintain and improve quality.

Our Group will further improve and innovate activities to maintain and enhance quality. We will establish strategies and objectives for creating new value for customers and responding to the evolving internal and external business environment and explicitly identify issues and problems that need to be tackled as we work towards achieving our strategies and objectives.

Our Group will use small group teams to solve the various issues and problems identified through daily management and policy management, thereby developing human resources.

Our Group will create the understanding and awareness of the mainstays of TQM, which are the prerequisites for maintaining and enhancing quality and activating improvements and innovation and then establish and implement a grade-specific education system.

We have established a Quality Committee to promote quality management, chaired by the officer in charge of the Quality Management Division, who is the chief executive in charge of quality management.

The Quality Committee formulates and issues policies and guidelines to optimize our functions from a company-wide perspective.

The Quality Assurance Conference is responsible for raising the level of quality assurance by sharing, discussing the causes of quality defects and promoting countermeasures.

Promotion System

Promotion SystemAt our major bases both in Japan and overseas, we are obtaining quality management system certifications such as ISO9001, IATF16949, and ISO13485 in accordance with the business requirements of the products we manufacture.

We believe that obtaining quality management systems, which are a mechanism for ensuring quality, is important for us to continue providing products and services that meet our customers' needs.

| Certification | Business Scope | Site |

|---|---|---|

| ISO9001 | Niterra Co., Ltd. ・IGNITE Compay ・Sensor Beyond Compay SparkTec WKS CO., LTD. CERAMIC SENSOR CO., LTD. |

Nagoya Plant |

| Komaki Plant | ||

| Satsuma Plant | ||

| Ise Plant | ||

| Nakatsugawa Plant | ||

| Tono Plant | ||

| SparkTec WKS CO., LTD. | Okusa Plant | |

| Satsuma Electrode Plant | ||

| IATF16949 | SparkTec WKS CO., LTD. | Nagoya Plant |

| Komaki Plant | ||

| Satsuma Plant | ||

| Nino Plant | ||

| Okusa Plant | ||

| CERAMIC SENSOR CO., LTD. | Komaki Plant | |

| Nakatsugawa Plant | ||

| Ise Plant |

| Certification | Business Scope | Site |

|---|---|---|

| ISO9001 | Niterra Co., Ltd. ・Niterra Ventures Compay ・Business Implementation Department |

Komaki Plant |

| NICHIWA KIKI CO., LTD. | Nagoya | |

| NTK CERAMIC CO., LTD. | Komaki Plant | |

| Kani Plant | ||

| Iijima Plant | ||

| NTK CERATEC CO., LTD. | Sendai West Plant | |

| Komaki Plant | ||

| MORIMURA SOFC TECHNOLOGY CO., LTD. | Komaki Plant | |

| Takenami Plant | ||

| ISO9001 | NANSEI CERAMIC CO., LTD. | Komaki Plant |

| ISO13485 | Ise Plant | |

| ISO13485 | NTK Medical CO., LTD. | Komaki Plant |

| Certification | Business Scope | Site |

|---|---|---|

| ISO9001 | Niterra ASIA Co., Ltd. | Thailand |

| IATF16949 | ||

| ISO9001 | PT Niterra Mobility Indonesia | Indonesia |

| IATF16949 | ||

| IATF16949 | Niterra(Shanghai)Co., Ltd. | Shanghai |

| IATF16949 | Niterra(Changshu)Co., Ltd. | Changshu |

| ISO9001 | WOOJIN INDUSTRY CO., LTD. | HWASEONG Plant |

| IATF16949 | Head Office & 1st Plant | |

| ANSAN 2nd Plant | ||

| SADONG Plant | ||

| ISO9001 | Niterra India Private Limited | India |

| IATF16949 | ||

| IATF16949 | Niterra South Africa (Pty) Ltd. | South Africa |

| ISO9001 | Niterra do Brasil Ltda | Brasil |

| IATF16949 | ||

| IATF16949 | Niterra North America, Inc. | USA |

| IATF16949 | Wells Vehicle Electronics L.P. | USA |

| Mexico | ||

| ISO9001 | Niterra Malaysia Berhad | Malaysia |

| IATF16949 | ||

| ISO9001 | Niterra (Thailand) Co., Ltd. | Thailand |

| IATF16949 | ||

| ISO9001 | Siam Niterra Co., Ltd. | Thailand |

| IATF16949 |

As part of our small group improvement activities, we are developing QC circle activities as "NQC Activities." (N denotes an initial letter of Nittoku).

NQC activities organize teams according to the problems and challenges at hand, with activities aimed at solving and achieving them. In addition to making tangible and intangible contributions to management, they also contribute to fostering employees.

The level of our activities has improved, with a gold medal at the All-Japan QC Circle Competition and the QC Circle Kaoru Ishikawa Award.

In addition, we are introducing the NQC Station, an IT tool for interactive communication, in order to strengthen NQC activities. We have systematized the proceedings of our activities and made it easy to understand the situation at hand. A portal site function has also been provided to enable circle members to obtain useful information and materials for their activities at any time.

To improve our employee’s quality control and foster employees capable of creating products and services that meet the needs of our customers and society, a variety of training is conducted related to quality control based on the concept of "manufacturing is fostering people".

Beginning with training for engineers to acquire practical skills in product realization concepts and procedures and quality control methods, as well as periodic training sessions, depending on the type of job and level of responsibility. Also, to improve through continuous upgrading of knowledge and practical skills required to maintain and improve quality. Aiming to improve the overall quality of the product.

We also offer our suppliers quality training and practical support for problem-solving so that they provide us with consistently high-quality parts and materials based on continuous quality improvement.

We hold quality activity events during Japan’s Quality Month in November, and also throughout the year.

Past quality exhibitions were held at our sites, but in consideration of preventative measures against COVID-19 and for convenience we have changed to holding exhibitions online.

We share our approaches to quality as well as the diverse quality-related initiatives in workplaces in order to maintain and improve quality awareness.

We also promote activities to maintain and enhance quality while engaging all employees through quality slogans and a range of other events.

Appropriate measurement is an essential part of manufacturing. In order to obtain reliable measurements, it is important that employees involved in manufacturing know the correct measurement techniques and proper measurement management. Therefore, we are strengthening our quality assurance system by nurturing human resources who understand the importance of measurement management and have correct measurement techniques, managing the accuracy of measuring instruments, and improving the measurement management system to improve and stabilize accuracy.

In FY2024, Measurement & Instrument Engineering Section Corporate Quality Control Department Business Support Company, Niterra Co., Ltd. obtained calibration business registration in the length scope of the Japan Calibration Service System (JCSS), a measurement law traceability system based on the Measurement Act.

NITE(), plays as the accreditation body of JCSS and conducts accreditation process with the system conforming to ISO/IEC 17011 and relevant international criteria. JCSS, Accredited Calibration Laboratories meet the requirements laid down in the Measurement Act as well as those of ISO/IEC 17025.

We will continue to strengthen our quality assurance system by improving and stabilizing the accuracy of our measurement technology.

To help trainees, acquire the necessary knowledge and skills at the right time, the Monozukuri Education and Training Center has a curriculum that covers the topics of safety, quality, maintenance, and improvement. We provide pre-assignment training, for new employees, that places "discipline" as the foundation of training, in order to cultivate human resources that become socially responsible, follow procedures, and place importance on quality.

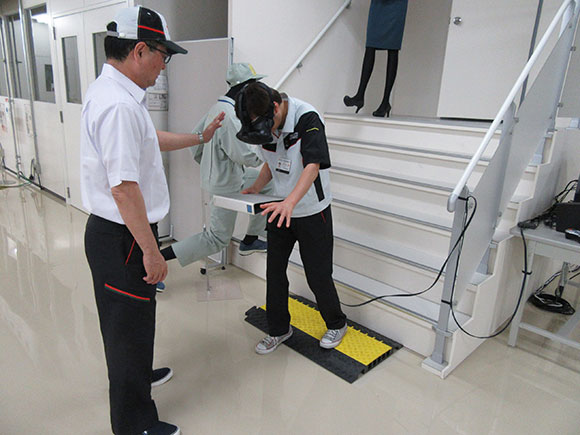

Safety training is conducted with zero industrial accidents in mind, with the guideline of "cultivating employees who can think and anticipate danger by honing their sensitivity before they act". We are working to improve the content of our education and training by introducing virtual reality (VR) and incorporating hands-on training to give employees more realistic experience of accidents such as falls and other accidents.

We are striving to provide valuable education while being flexible. We responded to the COVID-19 pandemic by introducing web-based lectures and other methods.

Monozukuri Education and Training

Monozukuri Education and Training VR experience

VR experience