We aim to eliminate occupational accidents, and in FY2023 our group had 46 accidents (previous year: 44). The number of accidents resulted in 21 cases of lost-time incidents (20 in the previous year) and 25 cases of no lost-time incidents (24 in the previous year), none of which resulted in death.

When an occupational accident occurred, the workplace and the Environmental Safety Department investigated the facts based on reports from the workplace and took appropriate countermeasures and other measures. In addition, an "Injury Report" summarizing the details and circumstances of the accident and a " Root Cause Analysis & Countermeasure Report" describing permanent measures and other information were distributed to all Group employees to raise awareness and prevent recurrence.

In FY 2023, five occupational accidents occurred (previous fiscal year: three accidents), and the total frequency rate was 0.69 (previous fiscal year: 0.42). Disasters occurred while adjusting equipment and during non-routine work, etc.

Frequency Rate of Injuries

Frequency Rate of InjuriesIn FY 2023, 29 occupational accidents occurred (previous fiscal year: 27 accidents). Accidents occurred during adjustment and cleaning of production facilities.

In FY 2023, 12 occupational accidents occurred (previous fiscal year: 14 accidents). The disasters occurred during adjustment and setup of production facilities, etc.

| FY2022 | FY2023 | |||

|---|---|---|---|---|

| Lost Time Incidents | No Lost Time Incidents | Lost Time Incidents | No Lost Time Incidents | |

| Niterra Co., Ltd. | 0 | 3 | 1 | 4 |

| Status of Group Companies in Japan | 12 | 15 | 12 | 17 |

| Overseas Group Companies | 8 | 6 | 8 | 4 |

| FY2022 | FY2023 | |

|---|---|---|

| Niterra Co., Ltd. | 0.42 | 0.69 |

| Status of Group Companies in Japan | 1.23 | 2.83 |

* Our calculation of lost-time injuries frequency rate, total frequency rate and number of deaths were reviewed by Japan Quality Assurance Organization (JQA) and we received the following verification report.

Risk assessment (RA) is the core activity of our occupational health and safety management system (OHSMS).

We have reviewed health and safety potential risks resulting from workplace equipment, chemical substances, and work at every workplace including both existing and new businesses, and work at every workplace and evaluated them to take hardware/software countermeasures (residual risk management), prioritizing the most dangerous risks.

Also, the head of the workplace has conducted work observations and reviewed the results of RA.

We conduct working environment measurements based on laws and regulations, targeting workplaces that handle chemical substances and workplaces subject to significant dust pollution and severe noise. Plants and workplaces that have been classified in the second or third management category are promoting improvements throughout the Nitera Group with the aim of moving to the first management category by sharing improvement measures at other workplaces.

We also take measures to prevent cases of heat stroke in the summer by measuring the humidity and temperature in hot workplaces, encouraging an adequate intake of water and salt, providing cooling gear and the like.

In our offices, we appropriately control the level of lighting, temperature and humidity to ensure that the environment is suited to the work. In winter, we install humidifiers to help prevent the spread of colds and influenza.

We conducted a variety of educational and training activities with the aim of building a safety culture from the view point of "people," "products" and "systems". Not only to prevent the recurrence of injuries, but to prevent them from occurring.

The program is implemented for new employees, third year, tenth year, managers, section managers and supervisors.

The same trainings are provided throughout the Niterra Group.

We are working to prevent industrial accidents by enhancing specialized training on chemical substances.

The use of hazard simulation machines, which are designed for simulations of accidents that may occur in a workplace, such as being pinched or entangled, allows trainees to experience the fear of having an accident, which is difficult to describe in words. Trainees can also learn how to avoid accidents.

In addition to 29 types of hazard simulation machines, two types of machines to check the wearing of protective equipment are available.

With the work style reform, we held the exhibition online. Efforts and case studies related to health and safety, environment are introduced to foster employees who will act on their own.

All employees are given this book, and it is read together in each workplace, leading to safe behavior for each employee.

In response to diversification, the book is translated into English and Portuguese. A web version is also available.

<Examples of Listed Contents>

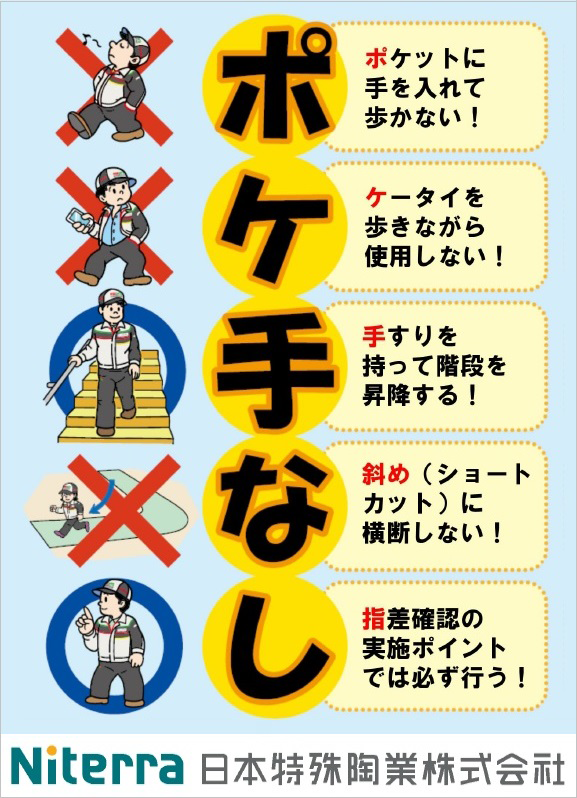

We conduct activities that comply with the rules to create safe and secure workplaces and employees. To prevent walking related injuries with a focus on “Po・Ke・Te・Na・Shi” awareness. In particular, we are promoting pointing and calling.

Managers and supervisors on the workplace also carry out workplace patrols, risk prediction and share examples of Hiyari-Hatto (near misses), acting as the leaders of workplace health and safety management.

" Po・Ke・Te・Na・Shi " awareness poster

" Po・Ke・Te・Na・Shi " awareness poster